Condition

The .45 2.0

The .45 Super was born out of the desire to update the venerable cartridge that fathered it. The .45 ACP was developed in 1906, because of this the .45 ACP has thinner walls than modern case designs, and is only able to handle lower pressures when compared to more modern pistol calibers. While the .45 ACP does have a large case capacity it is only able to handle a maximum of 22,000 copper units of pressure. Comparatively modern cartridges, using nitrocellulose powders, are able to handle and generate pressures of up to 39,000 CUP. Seeing the potential for improving the venerable .45 ACP, firearms writer Dean Grennell with the assistance of Tom Ferguson and Ace Hindman sought to use modern powders to improve the performance on target of the aging yet still popular pistol round. What they produced the, .45 Super, was able to hit faster and harder than the hottest 45 ACP loadings.

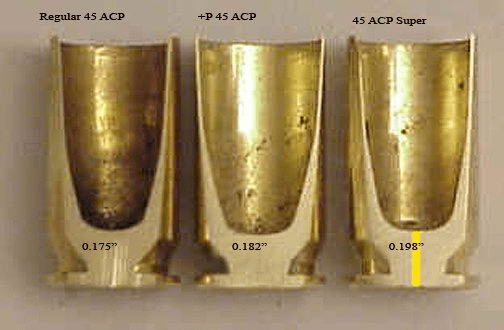

Cutway showing measurements of the .45 Super Case Webbing. Externally it looks identical to the .45 ACP.

Table of Contents

Overcoming Limitations

In 1988, when Dean Grenneell and his teams sought to build the .45 Super they wanted to solve a number of perceived problems with its parent cartridge. The inherently thin walls posed a problem when containing the pressures they wanted the new cartridge to deal with. Many 1911 and similar pistol designs have an unsupported feed ramp, with higher pressure loads this can lead to “smiling” cases where the lower side of the case wall that was unsupported expands out at best, or a “Kaboom” at worst.

To combat this Grennell shortened brass from the more recently developed .451 Detonics cartridge. This allowed the .45 Super to contain increased pressures, the end result was a cartridge capable of handling up to 28,000 psi. However necessary modifications did not end there the 1911 pistol designs that were tested included a new chamber and barrel design that specifically supported the head of the case. A heavier recoil spring was added and an improved firing pin that was added as well. The new design of the firing pin helps to prevent material from the primer from flowing back into the firing pins channel due to the high pressures of the cartridge.

The end result of this tinkering with its parent cartridge resulted in an average increase of about 23% in feet per second, 52% in foot pounds of force, and a 36% in the maximum psi.

Loading Data

While only recently moving out of the realm of being a wildcat cartridge, the main it to producers of .45 Super ammo are Underwood Ammunition and Buffalo Bore. Underwood Ammunition offers a number of different loadings and bullet styles, including 170 grain and controlled fracturing hollow points, 185 and 230 grain bonded jacketed hollow points, 200 grain extreme penetrator, and 255 Crane hard cast flat nose. Buffalo bore for its offerings offers three sizes of jacketed hollow point rounds, 185, 200, and 300 grain bullets a 230 grain flat nosed FMJ, and a hard cast flat nose version as well. Buffalo bore, because of its focus on personal defense, also uses flash suppressed powders in all of these loadings. For those looking to utilize the .45 Super for self-defense it will find many different options to choose from.

Detailed Loading Data can be found from Buffalo Bore, Tom Black also has written about the .45 Super’s performance as well as how to convert pistols (article from 2012) such as the Glock 21 to the more modern caliber.

Chambered Firearms

Because of the inherent increased pressure of the cartridge, it is recommended to avoid converting older 45 ACP firearms into this caliber. However ultimately converting a 45 ACP pistol into a .45 Super pistol is relatively easy.

The major necessary modification is an increased strength recoil spring. This prevents the higher pressure of the .45 Super from battering and ultimately damaging the slide of your pistol. Once this modification is complete most pistols chambered for 45 ACP will be able to deal with the recoil from the .45 Super.

However, it should be noted that barrels with an unsupported head should be avoided when attempting to fire the .45 Super, as the higher pressure in an unsupported head has the potential to lead it to a catastrophic failure, often referred to via shorthand as a “KA–BOOM”.

Such a failure in the webbing of a cartridge frequently results in the magazine being blown out the bottom of the pistol, and on occasion severe injury to the user.

Some pistols manufacturers such as Heckler & Koch and Springfield Armory, Inc. offer pistols that are rated to fire .45 Super without any modifications. For anyone seeking to modify their pistol to chamber .45 Super be sure to consult the pistols manufacture, before attempting any modifications as many pistol manufacturers consider their warranties null and void if these types of modifications are made.

Almost Dead

While the initial ideas of the .45 Super held great promise many of the issues with the 45 ACP that it sought to address, saw the .460 Rowland surpass the .45 Super in every single aspect that it sought to improve upon. Act Custom .45’s, Inc. trademarked the .45 Super name in 1994, being one of the top .45 Super manufacturers, but the company has since gone out of business. This leaves the cartridge with little support unless gun owners are willing to the extra mile to shoot it. We would call it dead if not for the factory ammo still available.