Condition

Andrew J. Grandy's Big Idea

The 1970s were a period of intense innovation in small arms development, and one of the most unique and ambitious ammunition concepts to emerge from this era was folded ammunition. Developed by Andrew J. Grandy at Frankford Arsenal, this radical departure from conventional cartridge design sought to optimize space, weight, and performance. Though ultimately unsuccessful in widespread adoption, folded ammunition remains a fascinating experiment in the evolution of firearms technology.

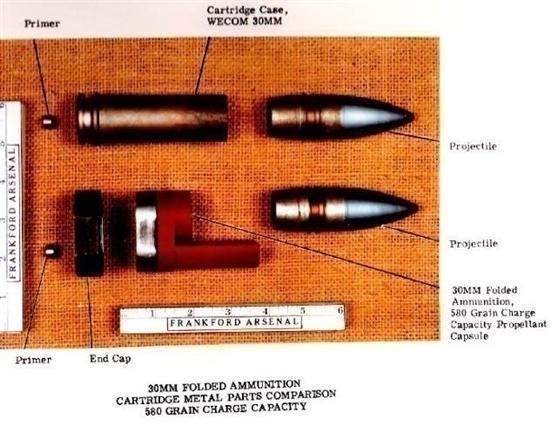

Above you can see a version of the folded ammunition concept in a 30mm round.

Table of Contents

Folded Ammo Video

The Genesis of Folded Ammunition

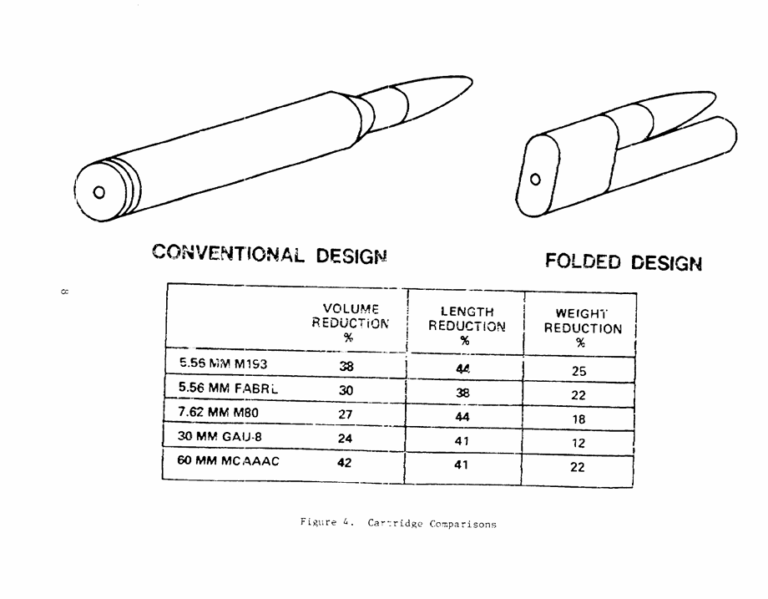

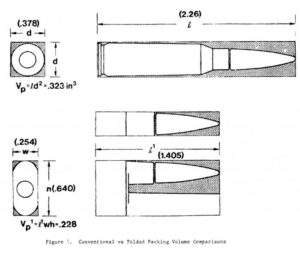

Traditional ammunition follows a simple, time-tested design: a projectile sits in front of a case filled with powder, which is ignited by a primer at the rear. However, Grandy and his team envisioned a more compact and efficient solution by relocating the propellant charge to the side of the projectile. This novel arrangement dramatically reduced the cartridge’s overall volume, with studies showing a 29% decrease in packing volume compared to conventional 5.56mm FABRL ammunition.

Above is a table from the September 1976 feasibility study that worked to prove the merits and identify the issues with the folded ammunition concept. In the table you can see that they were able to improve volume and weight with the concept. However, folded ammunition faced other headwinds.

At the heart of folded ammunition was the U-shaped cartridge case, which housed the powder charge in a side compartment rather than directly behind the bullet. This innovative configuration allowed for more efficient geometric packing, reducing weight and increasing the potential number of rounds a soldier could carry. This was especially appealing for military applications, where every ounce saved could mean additional gear, ammunition, or increased mobility.

Performance and Challenges

While the space and weight savings were significant, testing revealed several critical challenges that prevented folded ammunition from achieving mainstream adoption:

Slightly Reduced Performance

While some initial testing suggested a small increase in efficiency due to the altered combustion dynamics, gas flow restrictions reduced overall ballistic uniformity. The unique placement of the powder meant that burn rates were harder to control, sometimes leading to erratic velocity.

Manufacturing Difficulties

Unlike traditional brass cases, which have been manufactured using established methods for over a century, folded ammunition required complex polymer or steel fabrication techniques. Early prototypes struggled with case integrity and sealing, leading to reliability concerns.

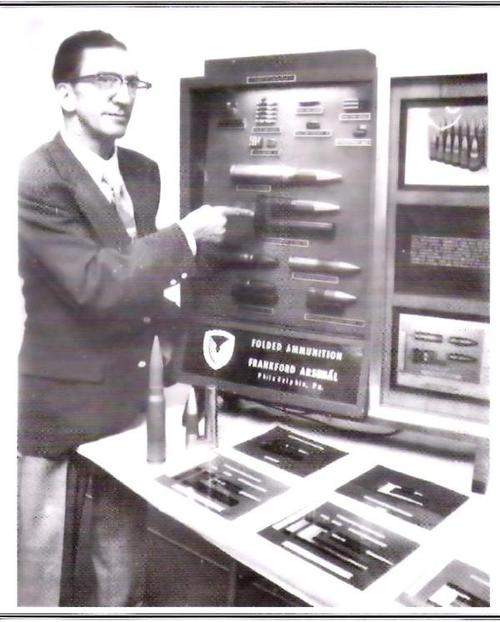

Andrew J. Grandy pictured above sometime in the 1970’s, most likely explaining the function of the folded ammunition concept. The version in the case and on the table is most likely a 30mm folded round.

Feeding and Ejection Issues

Conventional cartridges can be loaded into a chamber in any rotational orientation. In contrast, folded ammunition required precise alignment, complicating weapon adaptation. Modifications to standard weapons like the M16A1 and Belgian FAL demonstrated that the concept could be made to function but required significant modifications, such as custom magazines and bolt adjustments.

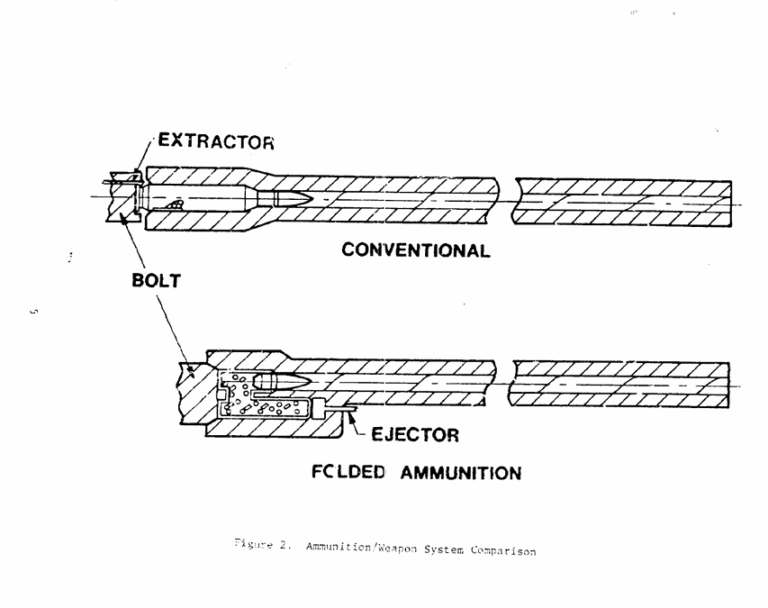

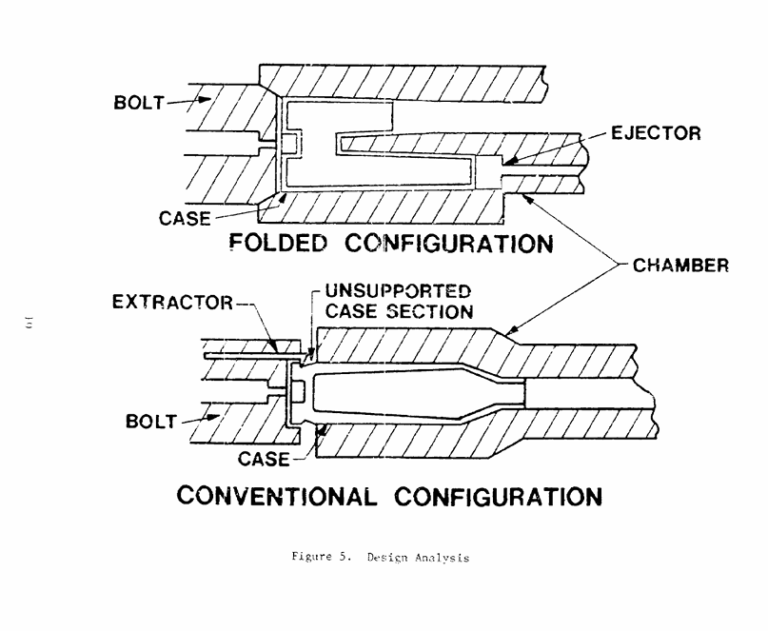

As you can see from the images below, the basic design of the bolt and chamber had to be radically changed for the folded ammunition concept. Removing the extractor from the bolt as well as removing the need for a traditional ejector. Instead, the ejector would be under the barrel, and as best I gather from the drawings, serve to extract and eject the cartridge out the bottom of the receiver.

The idea in theory would also simplify bolt design somewhat.

The folded ammunition concept introduced more complexity to building barrels and chambers.

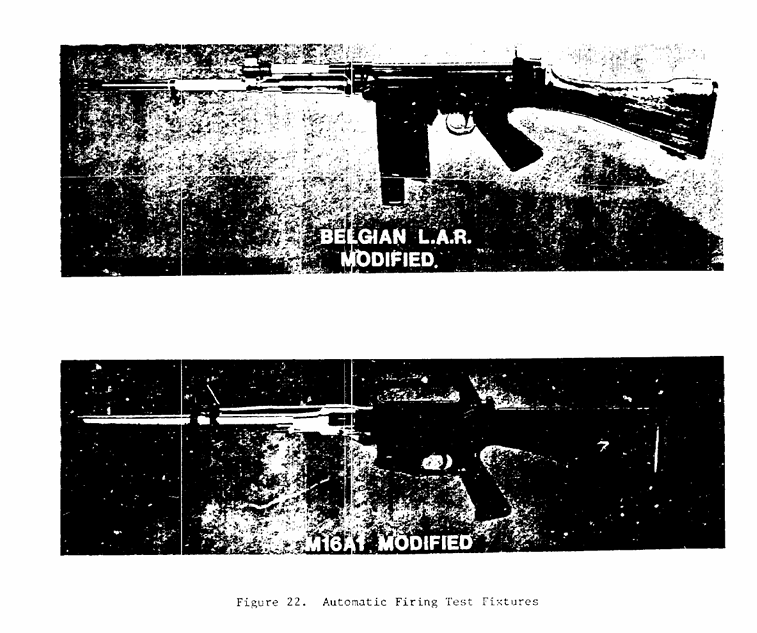

Pictured from the 1976 report, the modified M16A1 and the L.A.R. or FAL. Both images are of poor quality and don’t show just how much was modified to get the concept working.

Testing and Experimentation

To validate the feasibility of folded ammunition, extensive testing was conducted with modified M16A1 rifles and Belgian Light Automatic Rifles. These weapons were fitted with specialized 5.56mm barrels, custom magazines, and redesigned ejection systems to accommodate the unusual cartridge shape.

Firing tests revealed that folded ammunition could be successfully fed, fired, and ejected in automatic cycles, with a modified M16A1 achieving a cyclic rate of 706 rounds per minute. However, despite successful functioning, the overall benefits did not outweigh the complexities and costs of conversion.

Testing also included various chamber designs to determine if an optimal configuration could improve reliability and performance. A front-end case ejection system was explored, taking advantage of the folded cartridge’s shape. However, the modifications necessary to accommodate this system added further complications to weapon design.

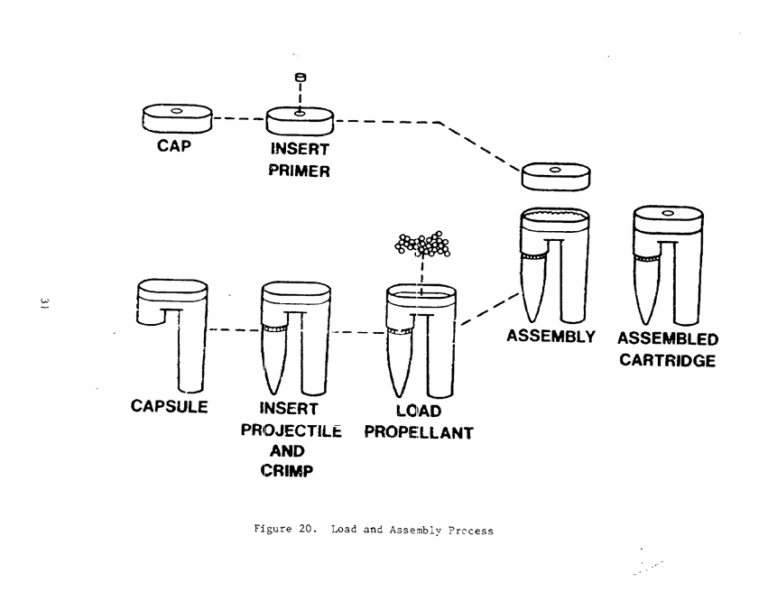

With a unique shape came a unique way of cartridge manufacturing. For a regular cartridge today crimping a bullet into the case would be one of the last steps in manufacturing.

The Evolution to Polymer Cases

Initially, steel weldments were used for case construction, but polymer variants were later developed to take advantage of reduced weight and cost. Injection-molded polymer cases allowed for lighter ammunition, a significant factor in military logistics. Despite this advancement, chambering problems due to the asymmetrical case shape continued to hinder widespread adoption.

Polymer cases also presented challenges with heat resistance and obturation, a critical issue for military applications. Unlike brass, which expands to form a tight seal against the chamber walls upon firing, polymers were less effective at containing high-pressure gas, potentially leading to reliability concerns in sustained fire scenarios.

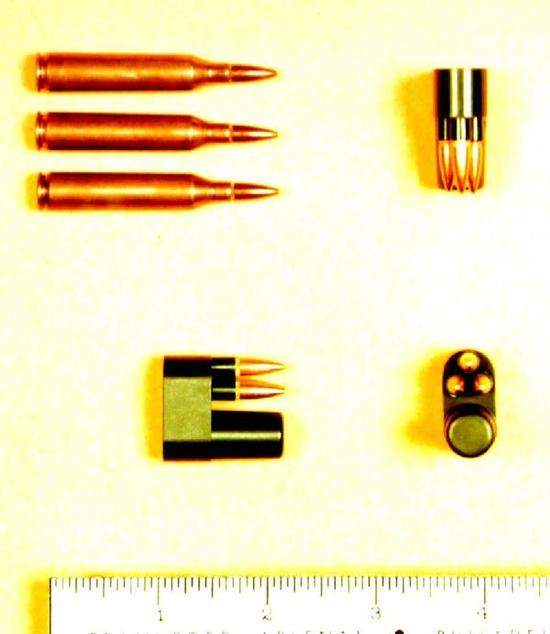

A black polymer triplex folded cartridge with a standard one.

Larger Caliber Applications and the Triplex Concept

While much of the focus was on 5.56mm ammunition, folded designs were also developed for 7.62mm, 30mm, and even experimental triplex rounds. The triplex concept, which fired three projectiles from a single combustion chamber, was an attempt to increase hit probability and combat effectiveness. However, the added complexity only exacerbated the logistical and mechanical challenges of the design.

In the 30mm variant, engineers sought to minimize the length of the gun action by making the ammunition as compact as possible. The propellant was housed in a crescent-shaped container beside the projectile, with a gas channel leading to the base of the bullet, facilitating more complete combustion. This configuration allowed for a 41% reduction in length and a 24% decrease in volume compared to the standard 30x173mm GAU-8/A round.

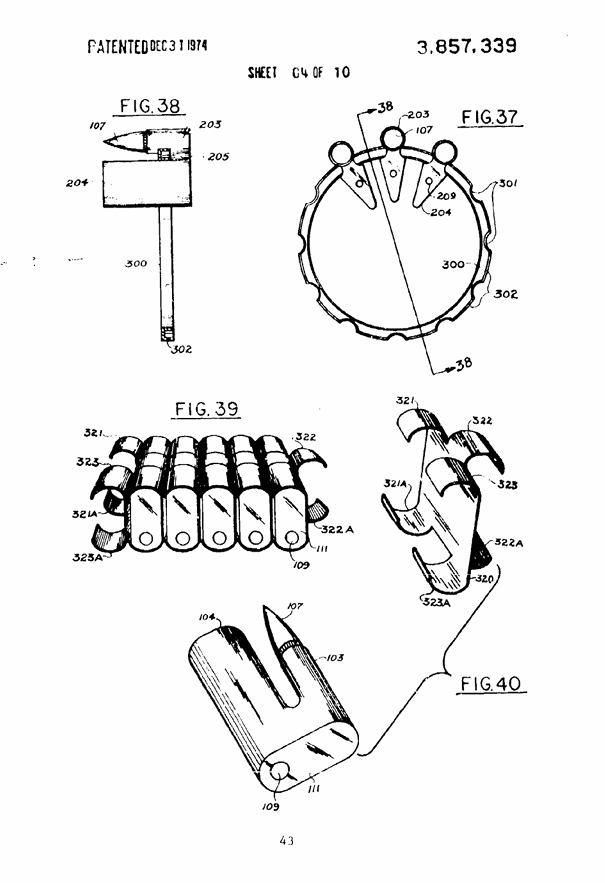

Standard magazines were considered along with other ways of feeding folded ammunition into a weapons system. Above is a drawing for a linked belt concept that could have been intended for crew served weapons.

Legacy and Lessons Learned

Though folded ammunition ultimately did not enter mass production, its development yielded valuable insights into space-efficient cartridge design and polymer case technologies. Today, with renewed interest in polymer-cased ammunition and alternative brass designs, some of the same goals that drove folded ammunition research are being pursued with modern materials and production techniques.

For example, True Velocity has a modern polymer-cased round, Sig-Sauer is using a hybrid brass and steel case for their new military caliber, and Shell Shock Brass has their own two-piece design.

Grandy’s work remains an important milestone in ammunition history, showcasing the ingenuity and ambition of the engineers at Frankford Arsenal. His patents, including US Patent 3,857,339, laid the groundwork for future research into unconventional cartridge designs. His later work at GTG Inc. demonstrated a continued passion for innovative firearm technologies.

Since the cases were polymer, integrating an interlocking system into them for use as a belt was also envisioned.

Policing the Brass - Conclusion

The folded ammunition experiment serves as a testament to the relentless drive for innovation in the firearms industry. Though it faced insurmountable challenges in its time, the fundamental ideas behind it continue to inform modern research into next-generation small arms ammunition. Whether through advances in polymer casing or alternative propellant configurations, the spirit of Grandy’s work remains alive in today’s pursuit of more effective and efficient ammunition.

While folded ammunition never became a standard-issue round, its legacy as a pioneering effort in ammunition miniaturization and efficiency continues to inspire researchers and engineers striving for the next breakthrough in firearms technology.

Huge hat tip to J.I. Boland for letting me know about this concept. You can see some of his work on his website and check him out on Instagram and Twitter